Process-1st Automation

Automation Built for Single-Use

- You have a problem -

Your equipment is running in 2025

but,

Your automation still lives in 1997

The team of engineers at Process-1st Automation is excited to announce a new approach for modular process automation integration in pharmaceutical manufacturing.

Our team has taken over 30 years of custom automation integration experience and created a modular approach that reconnects your process to your process equipment.

25 years ago, a seemingly small change happened in pharma, we started to see the introduction of single-use manufacturing systems. Process equipment stopped being stainless steel, custom configurations with hard piping flowing around a purpose built facility, and started being delivered on wheels. They were modular, flexible, adaptable, fast, single-use manufacturing operations.

Fast forward to today, and industry standard has become open ballroom production, manufacturing facilities changing equipment in between batches, and multiple process steps being executed on the same piece of equipment using different single-use flowkit configurations. The entire concept around manufacturing a pharmaceutical has fundamentally changed over the past 25 years. However, when you look at the process automation, it looks the exact same. The tech stack looks identical in 2025 to what made sense in the stainless-steel manufacturing facility of 1998.

Process-1st Automation is bringing the principle of modularity from process production into the automation space. We are able to do things faster, we are adaptable. Our platform operates at the speed of your facility, and we are able to make sure that when the status of current manufacturing evolves, you are ready to evolve with it.

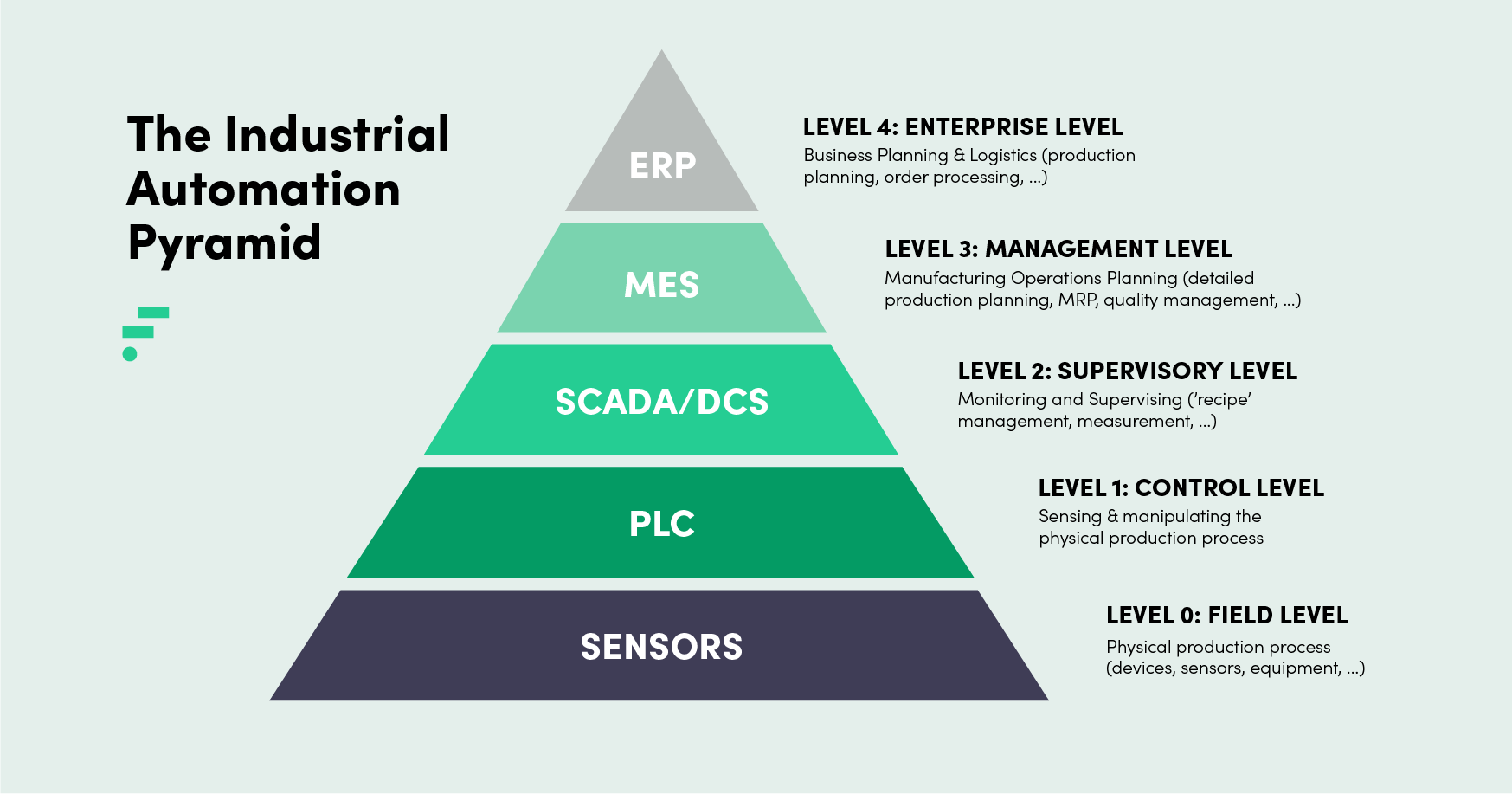

At its core, we have made one change. Process-1st Automation is putting the process first. When we look at the technology stack that exists in your facility today, we see the equipment, a DCS, and probably an MES or ERP system. This standard stack has existed for over 20 years, but when you look at that stack, the question we ask is, where is your process?

If you're having trouble finding it, it's because that wasn't so necessary when the process was fixed to the plant and stayed static for 20 to 30 years of operation. It was acceptable to allow the process to pass from PD to MSAT to IT to MES to DCS to SCADA to PLC and finally to execution. To keep up with your production, our engineering process looks like this PD to SCADA/PLC. One step, with no room for translational errors or lost time.

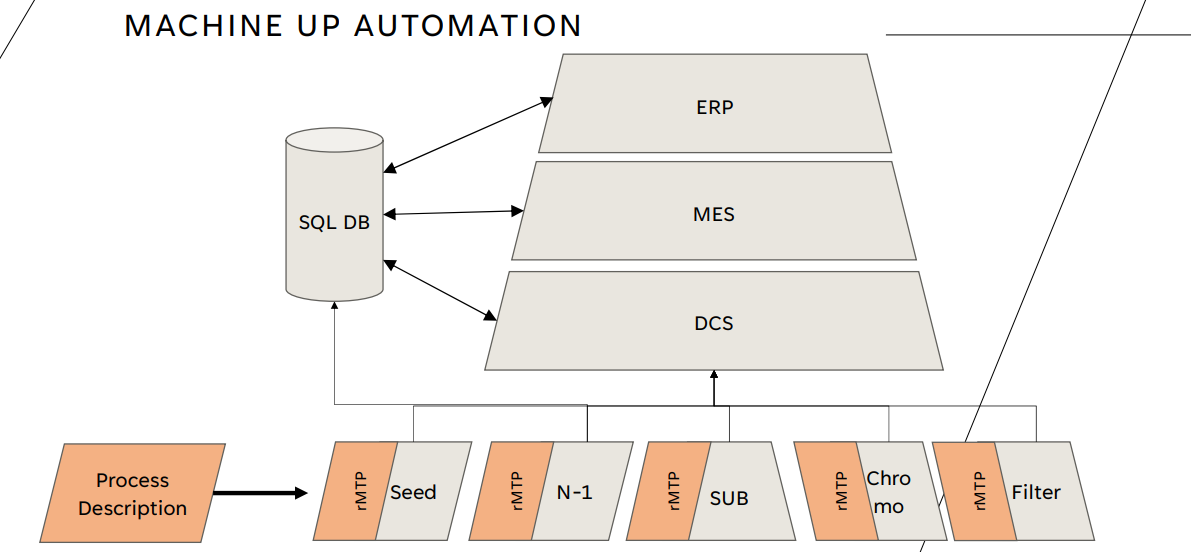

Our team is doing is taking your process, the equipment, the phases, the controls, the automation, the recipes, the semantics to use a general term, and we are attaching it to your individual pieces of equipment. Each individual unit operation becomes smart in and of itself, which then allows your smart skid to connect into your control system with all of the information that it needs to be able to execute, to be able to understand what's happening, to be able to collect the right data at the right time. Making this change, connecting the process to the process equipment, creates a facility that moves and adapts and changes just as fast as your process team can define what they want to do.

What's even more interesting is that Process-1st Automation can do this with the equipment you are already using, and on the distributed control system already in your facility. So you can leave your existing equipment in place, leave your existing control system in place, and still bring modularity to your facility.

We have already built the fundamental database and the software platform to unify your equipment. We have the team, the experience, and the plan ready to implement today. We can bring your automation to the same level of sophistication that you are already have in your manufacturing equipment.

If this sounds interesting, the team at Process-1st Automation is ready to show you what's possible. We can even demonstrate the complete integration process live and in front of you. We will show what this process looks like and how a small shift in paradigm changes everything.

We are looking forward to bringing this process to your facility to show you what's possible when the technology driving your facility automation becomes every bit as advanced as the process equipment you're already using.

-

Module Type Package (MTP)

A Module Type Package (MTP) is a non-proprietary standard that allows for the manufacturer-independent integration of process automation modules into a system

-

The Process-1st Method

Don’t take our word for it. Come watch a demo of what we can do, live and in real time.

-

Book your call today

Want to see you facility mapped out and implemented in our modular architecture? Schedule a call today

Want to Learn More?

Fill out your contact info and we will be in touch shortly. We can’t wait to hear from you!